Introduction

In the relentless push for smaller, faster, and more powerful electronics, efficient power management has become a cornerstone of modern design. From compact consumer gadgets to sprawling industrial systems, the ability to deliver clean, stable power is paramount. This demand is intensified by the dual challenges of miniaturization, which shrinks available board space, and the critical need for energy conservation. The intricate balance of delivering robust power while managing heat and maximizing efficiency defines the success of today's electronic products.

At the forefront of this challenge is the buck converter, a fundamental component for stepping down DC voltage. However, traditional designs are often insufficient for the demands of modern applications. This is where SWIFT (Switchers With Integrated FETs) buck converter technology provides a transformative solution. By integrating the power MOSFETs with the control circuitry, SWIFT converters deliver exceptional power density, simplify the design process, and achieve superior efficiency. They are indispensable for high-performance applications where every millimeter and milliwatt is critical.

This post explores the core principles of SWIFT buck converter technology, its key advantages, and its wide-ranging applications. We will also highlight how Fusion Worldwide, a global leader in electronic component distribution, empowers businesses to harness this technology. Through their comprehensive supply chain services, Fusion Worldwide ensures reliable access to critical power components, enabling companies to navigate the complexities of modern power design and accelerate their time to market.

Understanding SWIFT Buck Converter Technology

To appreciate SWIFT technology, one must first understand the basic buck converter: a DC-DC converter that efficiently steps down a higher input voltage. It uses rapid switching to store and release energy in an inductor, a method far more efficient than linear regulators that dissipate excess voltage as heat.

The SWIFT Advantage

SWIFT, or "Switchers With Integrated FETs," integrates the power MOSFETs (Field-Effect Transistors) with the controller IC. This integration provides several key advantages:

- High Power Density: Combining the controller and power switches allows for a smaller footprint, delivering more power in less space.

- Simplified Design: Fewer external components simplify the power supply design, saving board space, reducing complexity, and accelerating time-to-market.

- Ease of Use: The integrated solution is easier to implement, lowering the barrier for designers to incorporate advanced power management.

Key Features of SWIFT Converters

SWIFT converters incorporate several advanced features for superior performance:

- Synchronous Rectification: A second MOSFET replaces the traditional diode, significantly reducing power losses and improving efficiency, especially at high output currents.

- High Switching Frequencies: Operating at higher frequencies allows for smaller external components, contributing to miniaturization and faster transient response.

- Fast Transient Response: The converter can quickly adjust its output voltage during sudden load changes, ensuring system stability.

- Compact Size: The high level of integration results in exceptionally compact power solutions, vital for space-constrained applications.

Benefits Beyond the Board

The advantages of SWIFT technology extend beyond technical specifications. Improved efficiency leads to longer battery life and lower operating costs. Reduced heat generation simplifies thermal management, often eliminating the need for bulky heatsinks and fans. The inherent reliability of an integrated solution enhances the overall robustness and longevity of the end product.

The Pillars of High-Efficiency Power Design

Achieving high efficiency in power design is a multifaceted endeavor, relying on a combination of innovative technologies and meticulous engineering. SWIFT buck converters embody many of these principles, integrating them into a cohesive solution. Here, we delve into the core pillars that underpin high-efficiency power design, and how SWIFT technology leverages them.

Synchronous Switching: The Efficiency Multiplier

One of the most significant advancements in DC-DC conversion, and a hallmark of SWIFT technology, is synchronous switching. In a traditional buck converter, a diode is used to rectify the current during the off-cycle of the main switch. While simple, this diode introduces a voltage drop (typically 0.3V to 0.7V), which, when multiplied by the current flowing through it, results in significant power loss, especially at higher currents. This loss manifests as heat, reducing efficiency and requiring more robust thermal management.

Synchronous switching replaces this diode with a second MOSFET, synchronized with the main switching MOSFET. When the main switch turns off, the synchronous MOSFET turns on, providing a much lower resistance path for the current. The voltage drop across a MOSFET in its on-state (Vds_on) is significantly lower than that of a diode, often in the millivolt range. This dramatic reduction in conduction losses directly translates to higher efficiency, particularly crucial in applications with high output currents where even small voltage drops can lead to substantial power dissipation. The precise timing and control of these two MOSFETs are critical to maximizing efficiency and preventing shoot-through conditions, where both switches are momentarily on, creating a short circuit.

Power Management ICs (PMICs): The Integrated Brain

Power Management Integrated Circuits (PMICs) are highly integrated chips designed to manage the flow of electrical power within an electronic device. They are the

integrated brains of modern power systems, consolidating multiple power management functions into a single chip. These functions can include voltage regulation (buck, boost, buck-boost converters), battery charging, power sequencing, and power path management. SWIFT converters often incorporate PMIC functionalities, or are themselves a key component within a larger PMIC solution.

The integration offered by PMICs, especially when combined with SWIFT technology, brings several benefits:

- Reduced Board Space: By combining numerous discrete components into one IC, PMICs dramatically reduce the physical footprint required for power management circuitry, enabling smaller and more compact end products.

- Improved Efficiency: PMICs are designed for optimal power conversion and distribution, often incorporating advanced control algorithms that dynamically adjust power delivery based on system needs, thereby minimizing energy waste.

- Simplified Design and Manufacturing: A single PMIC replaces many individual components, simplifying the bill of materials (BOM), reducing assembly complexity, and improving manufacturing yields.

- Enhanced Reliability: Fewer components mean fewer potential points of failure, leading to more robust and reliable power solutions.

Voltage Regulation: Precision for Performance

Precise voltage regulation is paramount for the stable and reliable operation of sensitive electronic components, such as microprocessors, memory, and sensors. Fluctuations in voltage can lead to system instability, data corruption, or even permanent damage to components. SWIFT buck converters excel in providing highly accurate and stable output voltages, even under varying load conditions.

Their ability to maintain tight voltage regulation stems from several factors:

- Fast Transient Response: As discussed earlier, the rapid response of SWIFT converters to changes in load current ensures that the output voltage remains within specified tolerances, preventing performance degradation or system crashes.

- Advanced Control Loops: Modern SWIFT converters employ sophisticated control algorithms, often digital, that can quickly detect and correct deviations from the target output voltage. These control loops are optimized for stability and accuracy.

- Low Output Ripple: The integrated design and high switching frequencies contribute to a very low output voltage ripple, which is crucial for noise-sensitive applications. A cleaner power supply ensures optimal performance of digital and analog circuits.

Thermal Management: A Cooler Approach to Power

Heat is the nemesis of electronic components, degrading performance and shortening lifespan. In power conversion, efficiency and thermal management are inextricably linked. The more efficient a converter is, the less power it dissipates as heat, simplifying the thermal design requirements. SWIFT buck converters, with their inherent high efficiency, contribute significantly to better thermal management.

By minimizing power losses through synchronous rectification and optimized design, SWIFT converters generate less heat internally. This allows for:

- Smaller Heatsinks: In many cases, the need for large, bulky heatsinks can be reduced or eliminated entirely, further contributing to miniaturization and cost savings.

- Reduced Cooling Requirements: Lower heat generation means less reliance on active cooling solutions like fans, leading to quieter operation, lower power consumption for cooling, and improved system reliability.

- Extended Component Lifespan: Operating components at lower temperatures significantly extends their operational lifespan, reducing maintenance costs and improving overall system reliability.

In essence, the high efficiency of SWIFT buck converters is not just about saving energy; it's about enabling smaller, more reliable, and higher-performing electronic systems by effectively managing the thermal challenges inherent in power conversion. These pillars—synchronous switching, integrated PMICs, precise voltage regulation, and superior thermal management—collectively define the cutting edge of power design, with SWIFT technology at their forefront.

Applications of SWIFT Buck Converters

The versatility and efficiency of SWIFT buck converter technology have made it an indispensable component across a vast array of electronic applications. Its ability to deliver precise, high-current power in a compact and efficient manner addresses critical needs in diverse industries. Here are some key sectors where SWIFT buck converters are making a significant impact:

Consumer Electronics

In the fast-paced world of consumer electronics, miniaturization, extended battery life, and high performance are paramount. SWIFT buck converters are ideally suited for:

- Smartphones and Tablets: Powering the core processors, memory, and various subsystems, enabling longer usage times and thinner form factors.

- Laptops: Providing efficient power delivery to CPUs, GPUs, and other components, contributing to improved battery life and reduced heat.

- Wearable Devices: Their small size and high efficiency are crucial for smartwatches, fitness trackers, and other wearables where space and power consumption are severely constrained.

- Gaming Consoles: Delivering stable and efficient power to high-performance processors and graphics units, ensuring smooth gameplay and managing thermal output.

Industrial Applications

The industrial sector demands robust, reliable, and efficient power solutions for continuous operation and harsh environments. SWIFT buck converters are found in:

- Automation and Robotics: Powering motors, sensors, and control systems in industrial robots, automated assembly lines, and process control equipment, where precise voltage regulation and high efficiency are critical for performance and safety.

- Test and Measurement Equipment: Ensuring stable and accurate power for sensitive instrumentation, oscilloscopes, and data acquisition systems, where noise and voltage fluctuations can compromise measurement integrity.

- LED Lighting: Providing efficient and dimmable power for high-power LED arrays in industrial lighting, streetlights, and architectural illumination, contributing to energy savings and extended LED lifespan.

- Industrial PCs and Embedded Systems: Supplying reliable power to embedded processors and control boards in a wide range of industrial machinery.

Automotive

As vehicles become increasingly electrified and intelligent, the demand for sophisticated power management solutions grows. SWIFT buck converters play a vital role in:

- Infotainment Systems: Powering complex multimedia systems, navigation units, and display screens, requiring stable and efficient power delivery.

- Advanced Driver-Assistance Systems (ADAS): Supplying power to cameras, radar, lidar, and other sensors crucial for autonomous driving features, where reliability and precise power are non-negotiable.

- Electric Vehicle (EV) Charging Infrastructure: While not directly in the main power train, they are used in auxiliary power supplies and control circuits within EV charging stations and on-board chargers.

- Body Electronics: Managing power for various comfort and convenience features, such as power windows, seats, and climate control systems.

Telecommunications & Networking

The backbone of modern communication relies on high-performance, energy-efficient infrastructure. SWIFT buck converters are essential in:

- Base Stations: Providing efficient power to transceivers, digital signal processors, and other components in cellular base stations, crucial for minimizing energy consumption in always-on networks.

- Servers and Data Centers: Powering the multitude of processors, memory modules, and storage devices in server racks, where even marginal improvements in efficiency can lead to significant energy savings and reduced cooling costs across large installations.

- Network Routers and Switches: Ensuring stable power delivery to high-speed data processing units and communication interfaces, vital for maintaining network integrity and performance.

Medical Devices

Reliability, precision, and often portability are critical in medical applications. SWIFT buck converters are utilized in:

- Portable Medical Equipment: Such as patient monitors, infusion pumps, and diagnostic tools, where long battery life and compact size are essential for mobility and patient care.

- Diagnostic Tools: Providing stable and clean power for sensitive imaging equipment (e.g., ultrasound, MRI auxiliary circuits) and laboratory analysis instruments, where power quality directly impacts diagnostic accuracy.

- Implantable Devices (indirectly): While not directly in implantable devices due to their specific power requirements, the technology and principles derived from SWIFT converters influence the design of external charging and power management systems for such devices.

The widespread adoption of SWIFT buck converters across these diverse sectors underscores their importance as a foundational technology for efficient and high-performance power management in the modern electronic world. Their ability to meet stringent requirements for size, efficiency, and reliability makes them a preferred choice for designers pushing the boundaries of innovation.

Fusion Worldwide's Role in Powering Innovation

In an increasingly complex global supply chain, the ability to reliably source, manage, and optimize electronic components is as crucial as the technology itself. Fusion Worldwide stands as a pivotal partner in this ecosystem, empowering businesses to navigate the challenges of component procurement and lifecycle management, particularly in the specialized domain of power electronics like SWIFT buck converters. By offering a suite of comprehensive services, Fusion Worldwide ensures that manufacturers can consistently access the components they need, manage their inventory efficiently, and ultimately reduce costs, thereby accelerating innovation.

Sourcing Excellence: Bridging the Supply Gap

The global electronics industry is frequently impacted by supply chain disruptions, leading to component shortages and extended lead times. For critical components such as SWIFT buck converters, which are essential for the functionality and efficiency of countless devices, reliable sourcing is paramount. Fusion Worldwide excels in this area, leveraging its extensive global network and deep market intelligence to source even the most elusive or constrained parts. Whether it's a sudden surge in demand, an unforeseen production halt, or the need for end-of-life components, Fusion Worldwide acts as a crucial bridge, connecting manufacturers with the high-quality, authentic components they require to maintain production schedules and avoid costly delays. Their expertise in navigating the complexities of the open market ensures that clients receive genuine parts, mitigating the risks associated with counterfeit components.

Excess Mitigation: Transforming Liabilities into Assets

Managing excess electronic component inventory can be a significant financial burden for businesses. Overstocking ties up capital, incurs storage costs, and risks obsolescence. Fusion Worldwide provides robust excess mitigation solutions, transforming what would otherwise be a liability into a potential asset. They work with companies to identify, evaluate, and liquidate surplus inventory, including power management components. Through their global sales channels and strategic partnerships, they can find buyers for excess stock, recovering value and freeing up warehouse space and capital. This service is particularly valuable for specialized components like SWIFT buck converters, which, while in high demand, can become excess if project requirements change or production volumes are adjusted.

Inventory Management: Precision and Efficiency

Effective inventory management is key to operational efficiency and cost control. Fusion Worldwide offers tailored inventory management solutions that go beyond simple warehousing. They help clients optimize their stock levels, ensuring that critical components like SWIFT buck converters are available precisely when needed, without incurring excessive holding costs. This includes just-in-time (JIT) delivery, consignment programs, and vendor-managed inventory (VMI) services. By providing real-time visibility into inventory and demand forecasting, Fusion Worldwide enables manufacturers to reduce carrying costs, minimize the risk of stockouts, and streamline their production processes. This proactive approach to inventory ensures a steady supply of essential power components, supporting uninterrupted manufacturing and faster time-to-market.

Lifecycle Management: Sustaining Production from Cradle to Grave

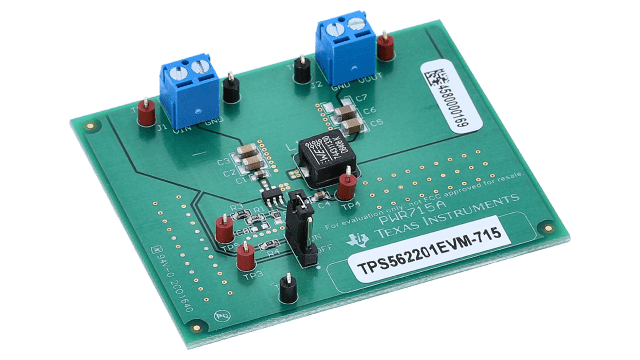

The lifecycle of electronic components can be complex, with parts moving through various stages from introduction to obsolescence. Fusion Worldwide offers comprehensive lifecycle management services, particularly vital for long-term projects and products with extended lifespans. They assist clients in managing the entire component journey, from initial design and procurement to end-of-life planning and last-time buys. For power components like the 4.5-V to 17-V, 8-A synchronous SWIFT™ buck converter, ensuring long-term availability and managing transitions to newer generations is critical. Fusion Worldwide helps identify potential obsolescence risks, secure necessary inventory, and find suitable alternatives, thereby preventing costly redesigns or production halts. This proactive management ensures continuity of supply and extends the viability of products in the market.

Cost Savings: A Holistic Approach to Value

Ultimately, Fusion Worldwide's services are designed to deliver significant cost savings to manufacturers. This is achieved through a holistic approach that encompasses several avenues:

- Optimized Sourcing: By finding the best prices and reliable suppliers, especially for hard-to-find components, they reduce procurement costs.

- Reduced Inventory Costs: Efficient inventory management and excess mitigation free up capital and reduce expenses associated with warehousing and obsolescence.

- Minimized Production Delays: Reliable access to components prevents costly production line stoppages and missed market opportunities.

- Risk Mitigation: By ensuring authenticity and managing supply chain risks, they prevent the financial repercussions of using counterfeit or faulty components.

- Streamlined Operations: Their services allow manufacturers to focus on their core competencies, reducing the overhead associated with complex supply chain management.

By partnering with Fusion Worldwide, businesses gain a strategic advantage in the competitive electronics market. Their expertise in navigating the intricacies of component supply, particularly for advanced power solutions like SWIFT buck converters, allows manufacturers to innovate faster, produce more efficiently, and achieve greater profitability. Fusion Worldwide is not just a supplier; they are a vital extension of their clients' supply chain, dedicated to powering their success.

Conclusion

The continuous evolution of electronics demands increasingly efficient, compact, and reliable power solutions. SWIFT buck converter technology exemplifies this progress, offering a highly effective method for voltage step-down with superior efficiency and integration. Its synchronous switching and integrated PMICs ensure precise voltage regulation and excellent thermal performance, making it vital for applications ranging from consumer devices to industrial automation.

High-efficiency power solutions offer benefits beyond energy savings, enabling smaller, lighter, and more robust electronic products, reducing operational costs, and fostering a sustainable technological ecosystem. For power management engineers, hardware architects, and product designers, understanding and utilizing technologies like SWIFT buck converters is essential for innovation and competitiveness.

Navigating the complexities of component sourcing and supply chains can be challenging. Fusion Worldwide provides crucial support, leveraging its global network and market intelligence to ensure access to critical components like the 4.5-V to 17-V, 8-A synchronous SWIFT™ buck converter. Their services, including excess mitigation, precise inventory management, and lifecycle support, are designed to optimize supply chains, reduce costs, and mitigate risks.

Partner with Fusion Worldwide to gain a strategic advantage in the electronics market. Their expertise in component supply, particularly for advanced power solutions, enables faster innovation, efficient production, and greater profitability.

Call to Action: Discover how Fusion Worldwide can empower your next-generation power designs. Visit fusionww.com or contact their experts for a consultation tailored to your needs. Power your innovation forward with Fusion Worldwide.

References

- [1] Texas Instruments. SWIFT DC/DC Converters Selector Guide. Available at: https://www.ti.com/lit/pdf/slvt165

- [2] DigiKey. Understanding SWIFT Step Down DC/DC Converters. Available at: https://www.digikey.com/en/ptm/t/texas-instruments/power-understanding-swift-step-down-dcdc-converters

- [3] Microchip Technology. PMIC - Power Management ICs. Available at: https://www.microchip.com/en-us/products/power-management/pmic-power-management-ics